APRIL AND MAY 2025 UPDATE

Moving Towards Production

Intro

Hi, everybody! It's Cooper again. Looks like we're combining April and May in today's update. We've been extremely heads-down this past April preparing a Betta Wire for RMRRF. We ended up with a machine we were really proud to be able to show off, and I'm super happy for that. It was great to see some of you there for the demo.

On that note, we're moving towards production with our Powercore V3s soon! We should be ready to order our first run of PCBs either today, or in the next few days. We have a few engineering validation units on hand that have been performing well.

Read on and we'll cover the rest of our developments.

Betta Wire

Tools

There has been a significant revision on the lower tool for the Betta Wire. We have moved from using a large, 24V, geared, waterproof, DC motor to two smaller motors of the same type as the upper tool.

The way the tool has been removed in the image is another huge quality of life improvement. All critical parts of the lower tool can be removed and worked on without having to change belt tension. We're going to try to make the top tool work the same way.

The large transparent object you see on the back of the tool is a resin printed waterproof enclosure. This is something we're going to include in the Betta Wire Kits. We know not everyone has or uses resin printers, so we'll be printing and assembling these.

This waterproof enclosure, in addition to allowing us to use the same motors on different points on the machine, allows us to more easily use motor current draw to calibrate wire tension. This means that we'll be able to achieve a more controlled WEDM process.

You can see some of the sealing features in this image. There are dual greased O-rings on the output shafts as well as greased face seals around the motors. These motors have been functioning well under water for some time now and we're pretty confident we've come up with a good solution.

Endstops

Our system uses water as a dielectric. Water is generally bad for electronics and should be kept away from them, so we're doing just that.

Introducing our the newest waterproof endstops! These endstops feature a conformal resin enclosure similar to our new motor enclosure.

Our previous design required potting of the endstops directly into your tool and motion component prints. This solution allows endstops to be uninstalled whenever is needed.

For a while, we were avoiding the use of resin prints, but the fact of the matter is that waterproofing is hard. We need to be able to use all the tools at our disposal in order to achieve our goals. We're likely to continue to expand our use of resin printing to facilitate waterproofing and dielectric control.

Works-Like Machine Build

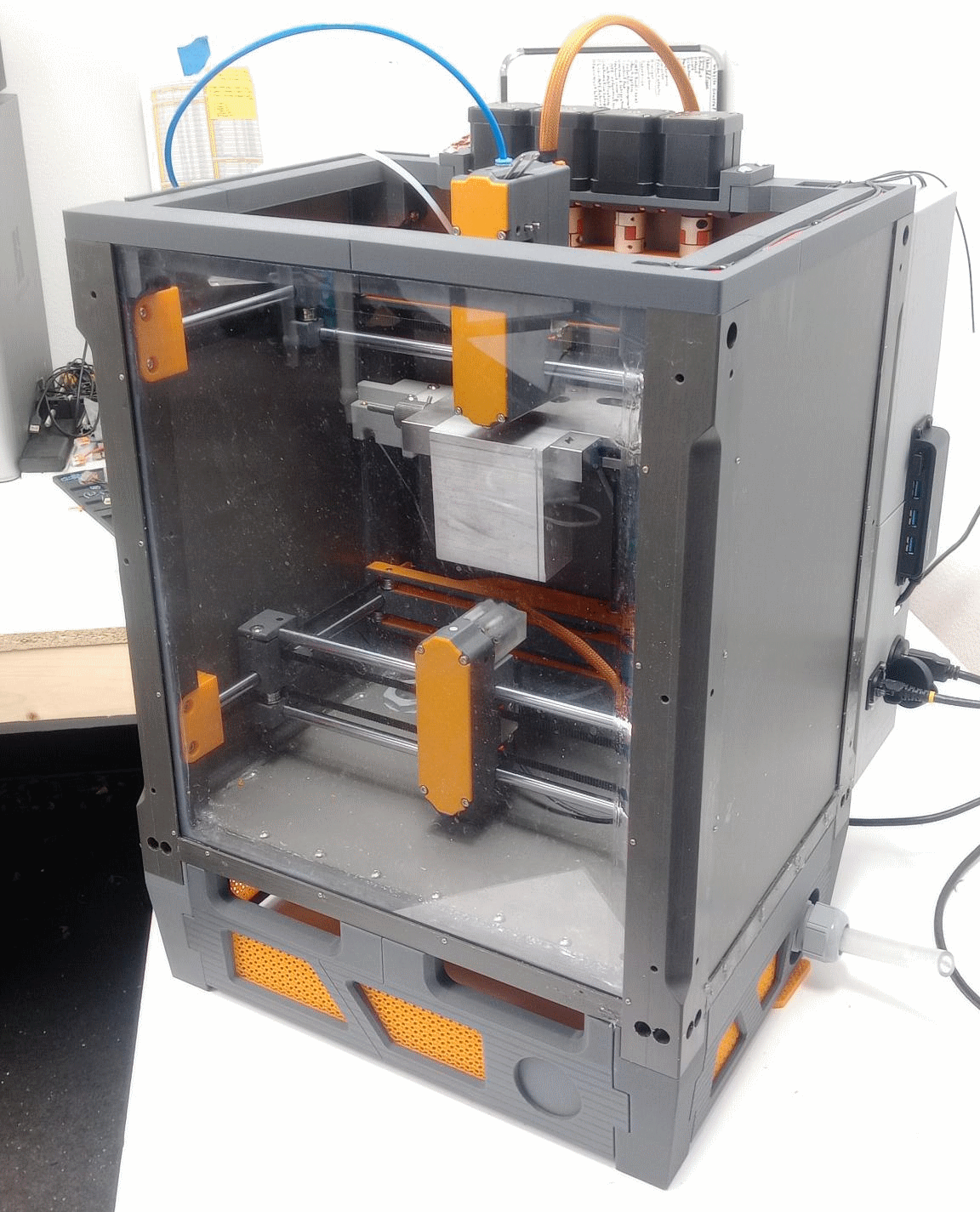

The overall machine has changed quite a bit in a really great way. We have fully machined aluminum pillars making up the corners of the machine.

These corner pillars provide a lot of rigidity to the design. All of our machined and laser cut components have been type III anodized. This will prevent any stray wire (say from a wire breakage during machining) from turning the whole frame into an electrode. This is pretty important to us.

Machine Control

On the LinuxCNC front, we are finally diving into macro development and human machine interface (HMI) refinement.

We have validated basic machine function and our first test cuts in 4 inch thick aluminum with LinuxCNC. We will shortly be proceeding with validation of closed loop controls with thicker material and harder to machine material like thicker steels. I'm especially excited by the idea that we could cut out hardened steel stamping dies!

Powercore V3

As I said before, the Powercore V3 is almost ready for production! We're ordering the first run of boards that we think will be viable for production shortly. We will then be performing extensive stress testing on the pre-production units.

Our testing will cover thermal stresses and thermal dissipation, long-term machining performance, and EMI/EMF.

Some of the last things required for the Powercore V3 outside of testing include laser engraving of pertinent markings and packaging design.

The new Powercore V3 is extremely rugged. I suspect that we'll be able to drop voidfill foam from our packaging and will be able to just have a snug box and polymailer. Any way we can reduce plastic in our packaging is good to me!

Wire Tool Kits

[UPDATED 25.06.02]

All wire tool kits will be receiving updates ported over from the Betta Wire Toolheads. We're looking to improve wire control and dielectric flow.

It likely won't be possible to completely integrate the same controls on the Wire Tool Kit when compared to the Betta Wire, but we do expect to have dual ceramic guides to significantly improve cut precision and consistency.

No photos on this yet as we're waiting to finish the Betta Wire prior to moving to our feature port.

Closing Thoughts

It feels like we've crossed the hardest point of development for our current round of products. We have a functional Powercore V3, our Betta Wire is already doing test cuts in thick material, and we have a clear path to beginning fulfillment.

I want to thank each and every one of you for your continued support and patience. We're soon going to have affordable desktop machines that can cut 4"+ thick hardened steel. This is going to be huge for the world.

Talk soon!

-Cooper